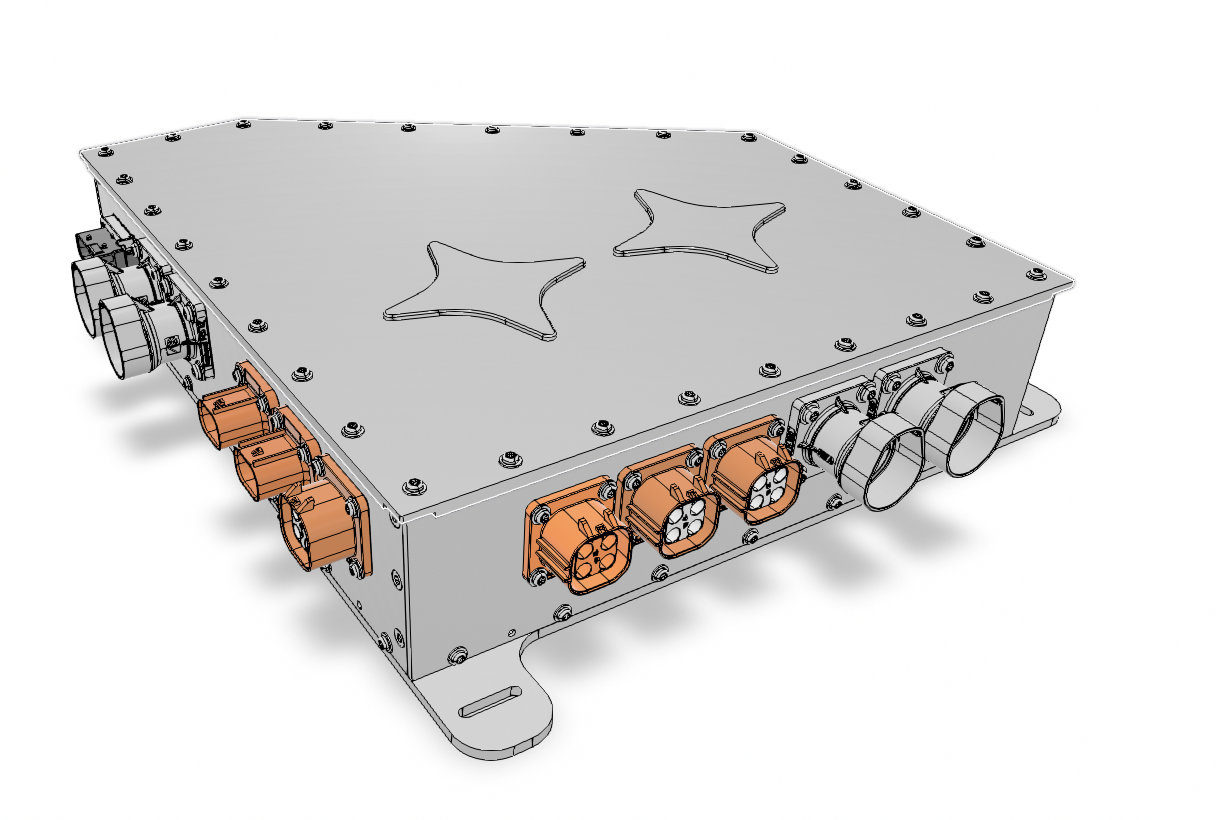

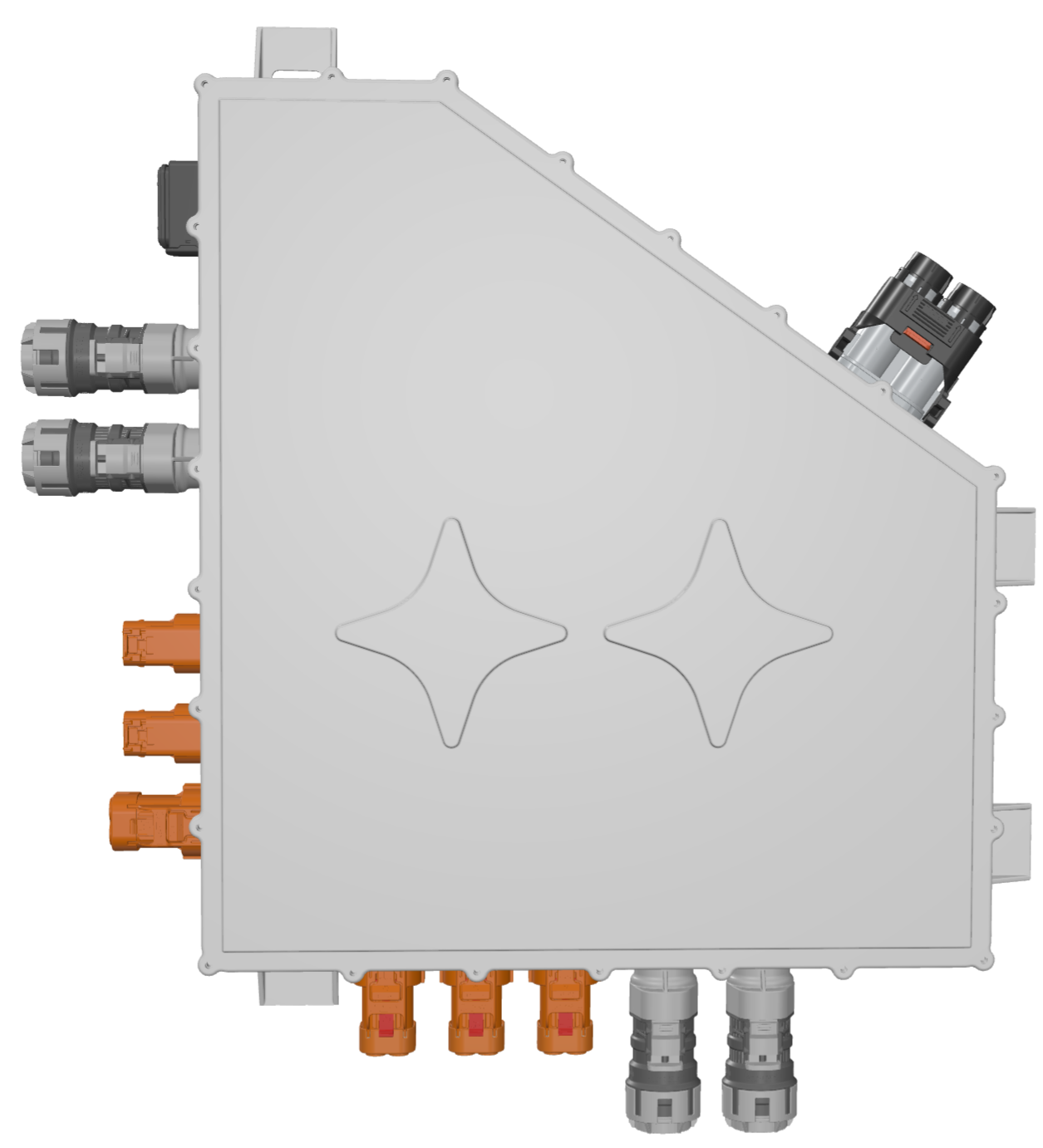

Beta 1 High Voltage Junction Box (HVJB) //

Beta 1 High Voltage Junction Box (HVJB) //

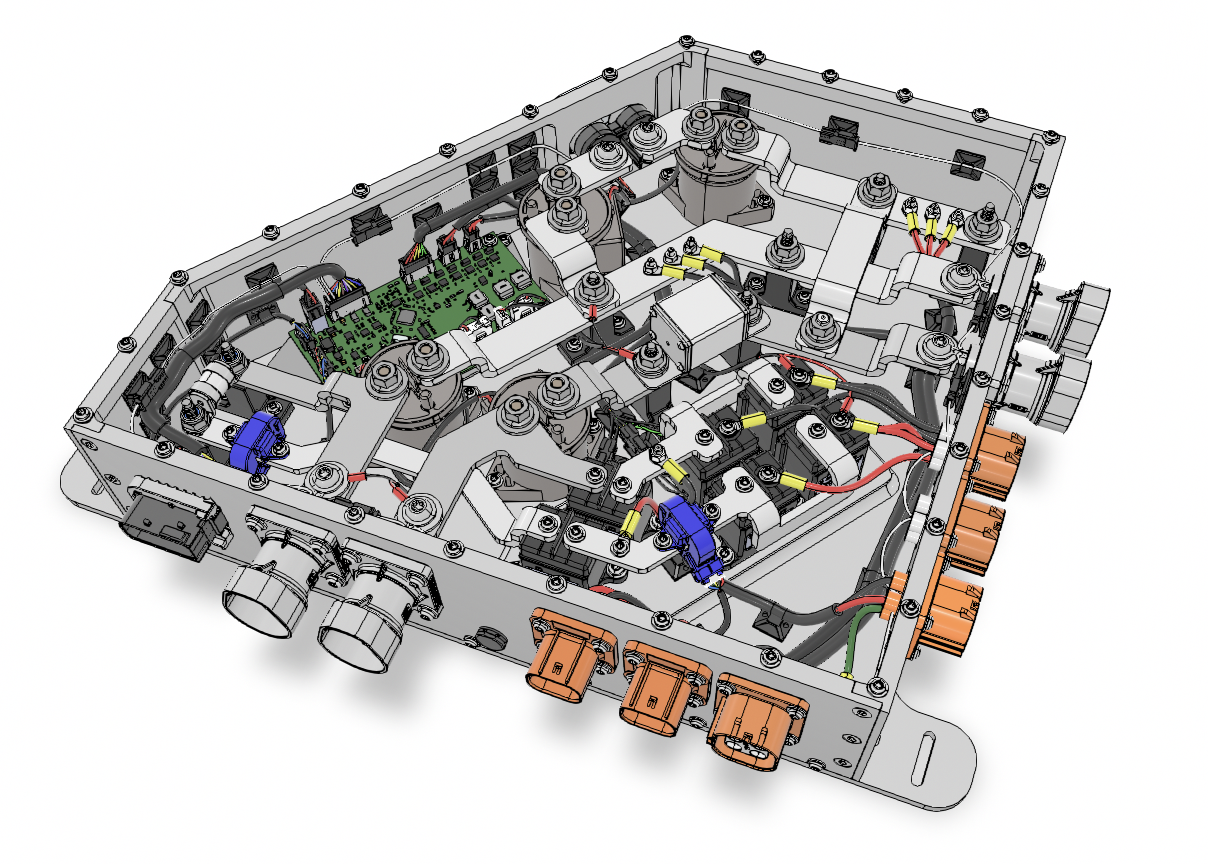

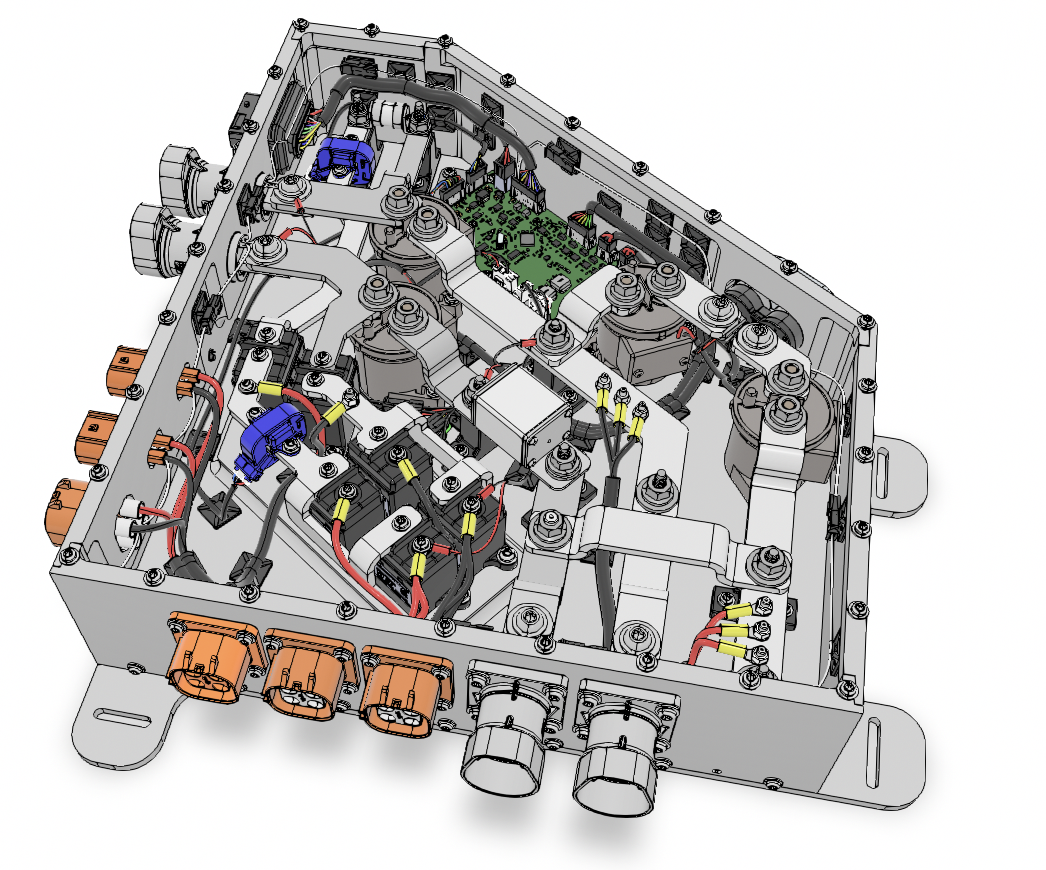

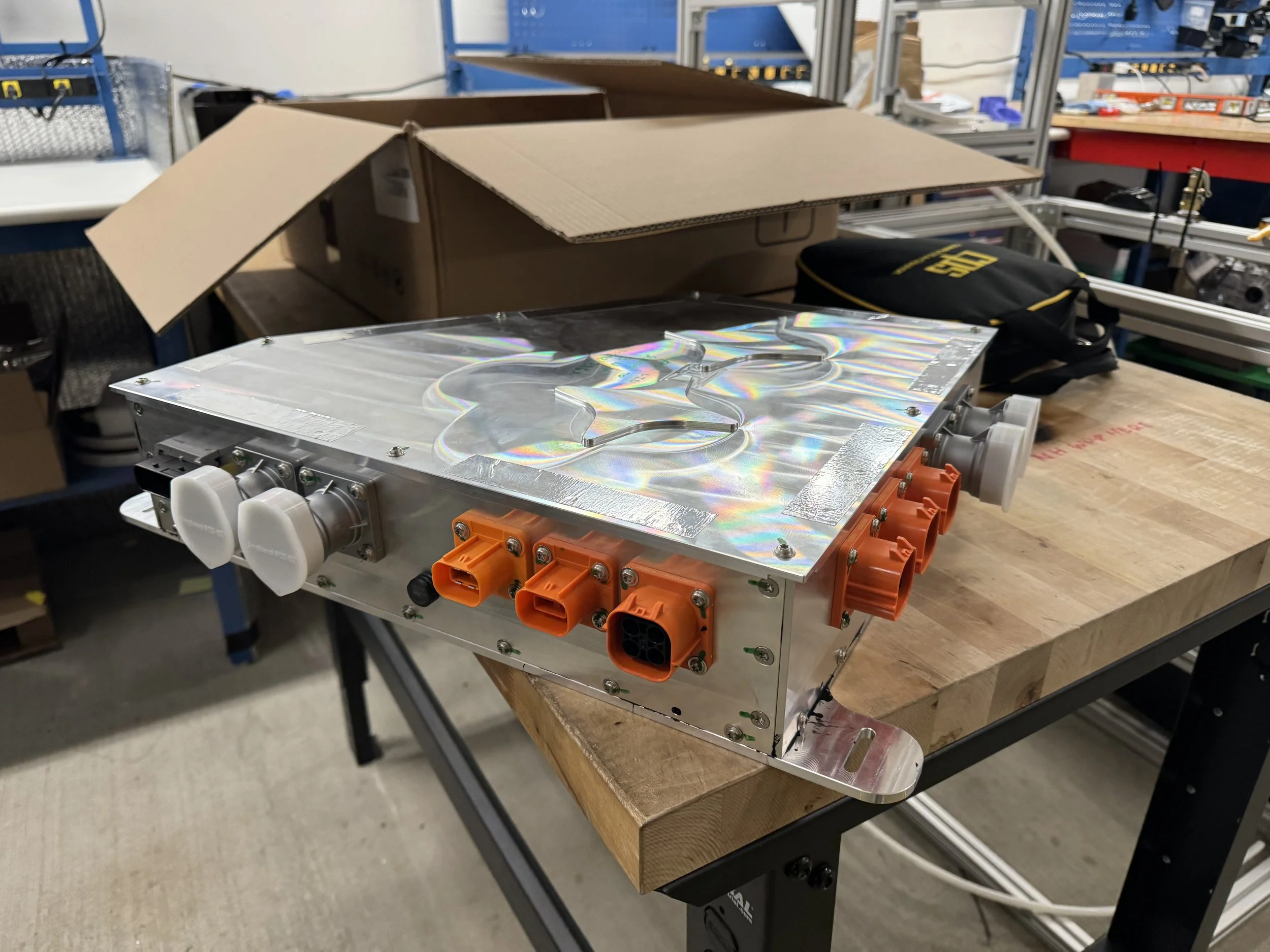

Sole design engineer of a fully custom High Voltage Junction Box used in our Beta 1 Builds.

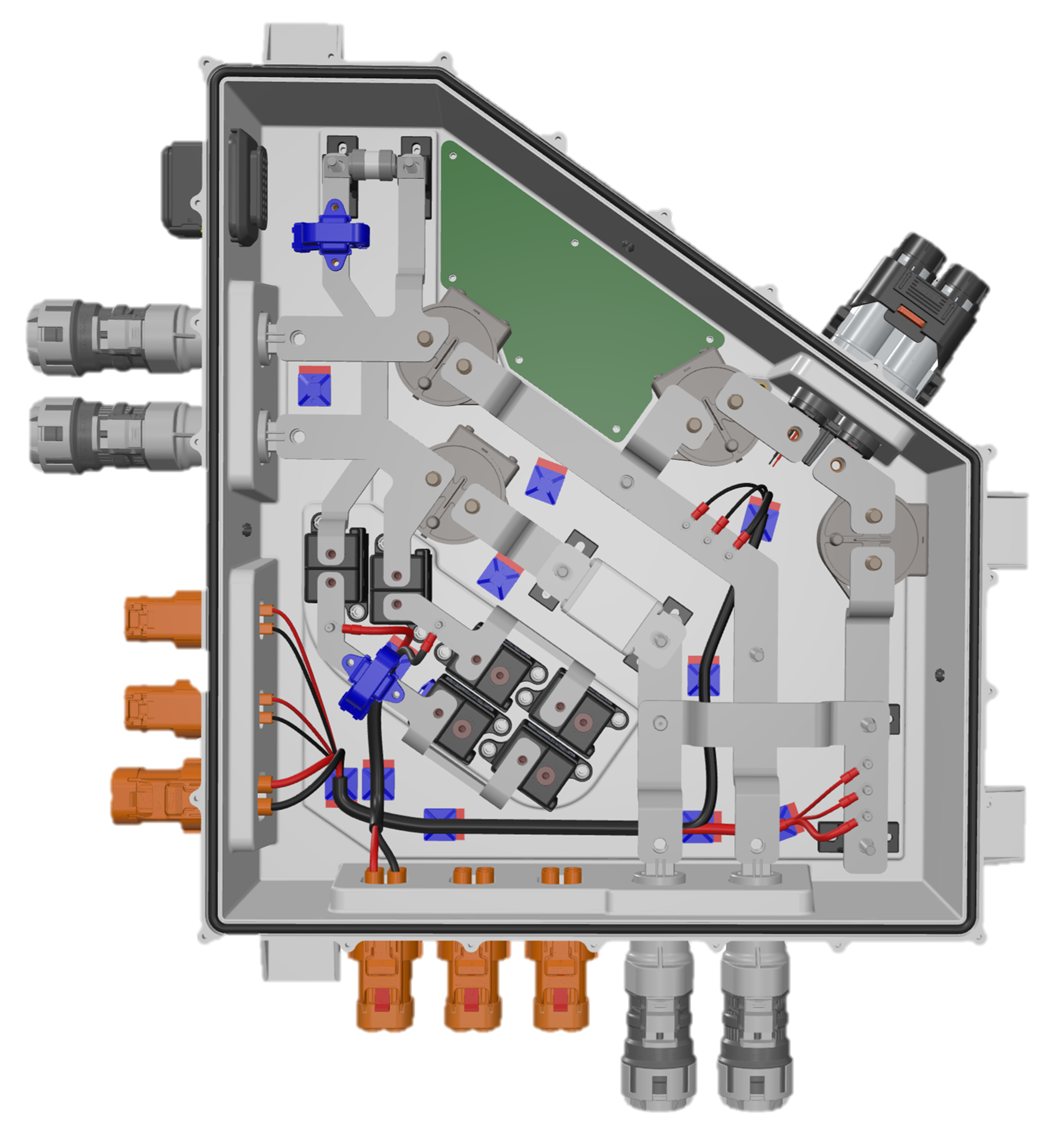

I designed and architected everything from scratch. Everything from the layout, to the busbars, to the billet aluminum panels, to the form factor of the PCB board and its packaging and integration, as well as all the internal harnessing. All this while still meeting all durability and safety requirements.

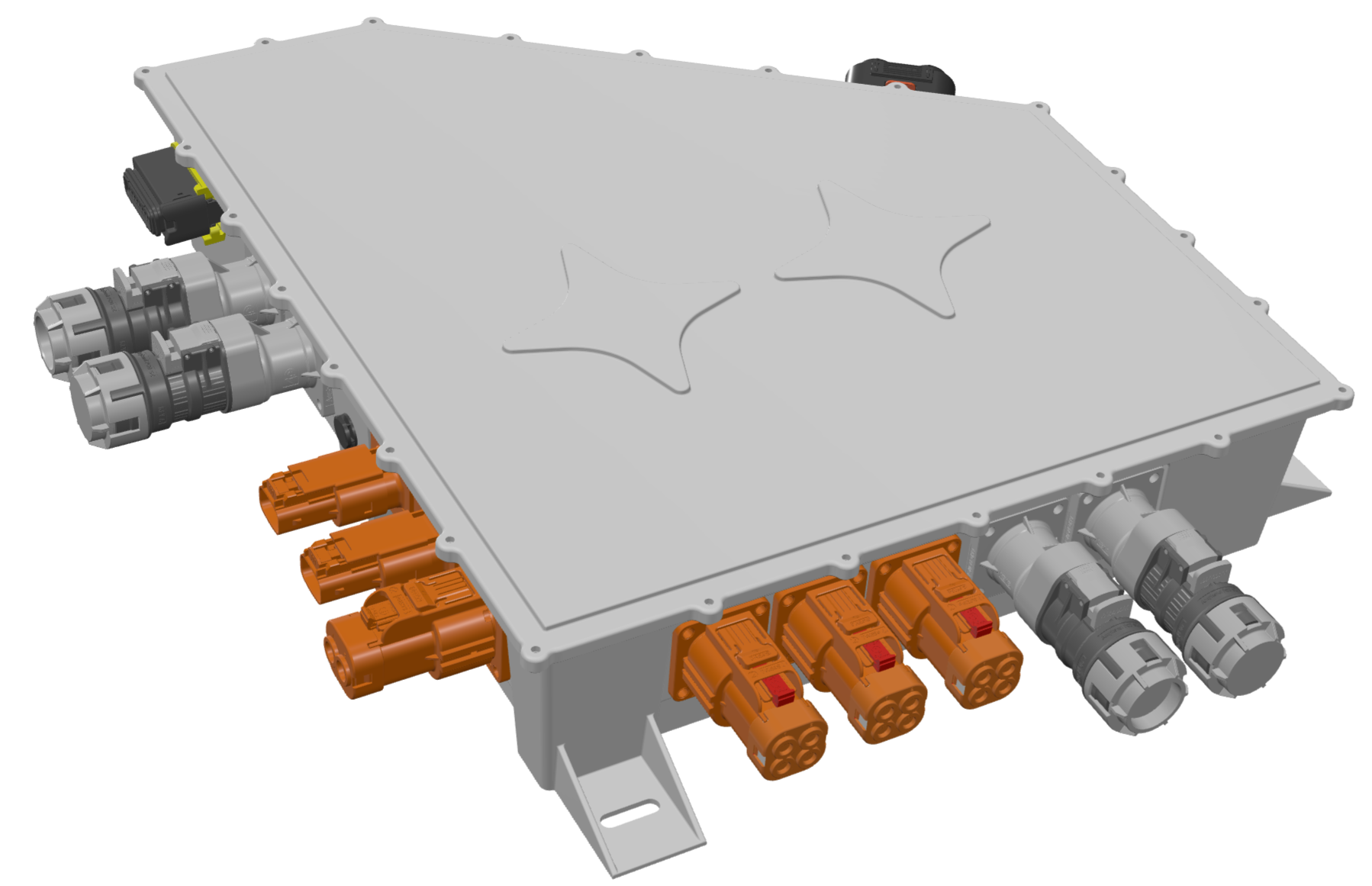

The HVJB facilitates power flow in multiple different scenarios. These are:

HVDC power flowing to the HV battery from various sources, including

From the charge port (DC fast charging)

From the On-board charger (AC charging)

From the 12v DC-DC converter (in boost mode)

From the drive unit (regenerative braking)

HVDC power flowing from the battery pack to various HV components, including:

Drive unit (motoring)

12v DC-DC converter (in buck mode)

OBC (in V2X mode)

HV compressor

HV sensing to check HVDC voltage, and confirm AC vs DC input on NACS charge port

HV isolation check to test HV isolation to ground

Current sensing to determine amperage of current flow (AC and DC)

AC power flow from AC mains (L1/L2 AC connections) to OBC and AC junction box

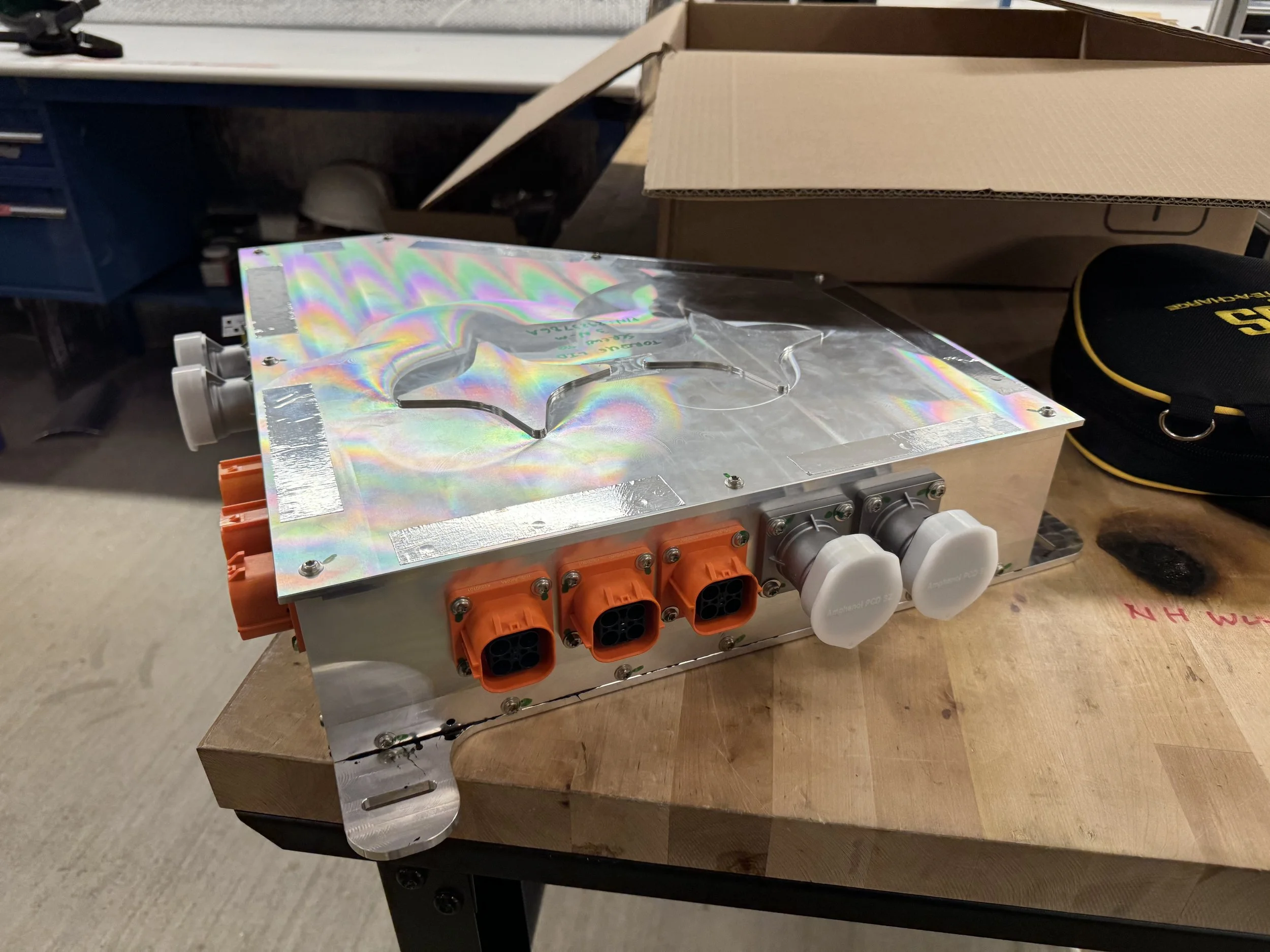

Beta 2 HVJB

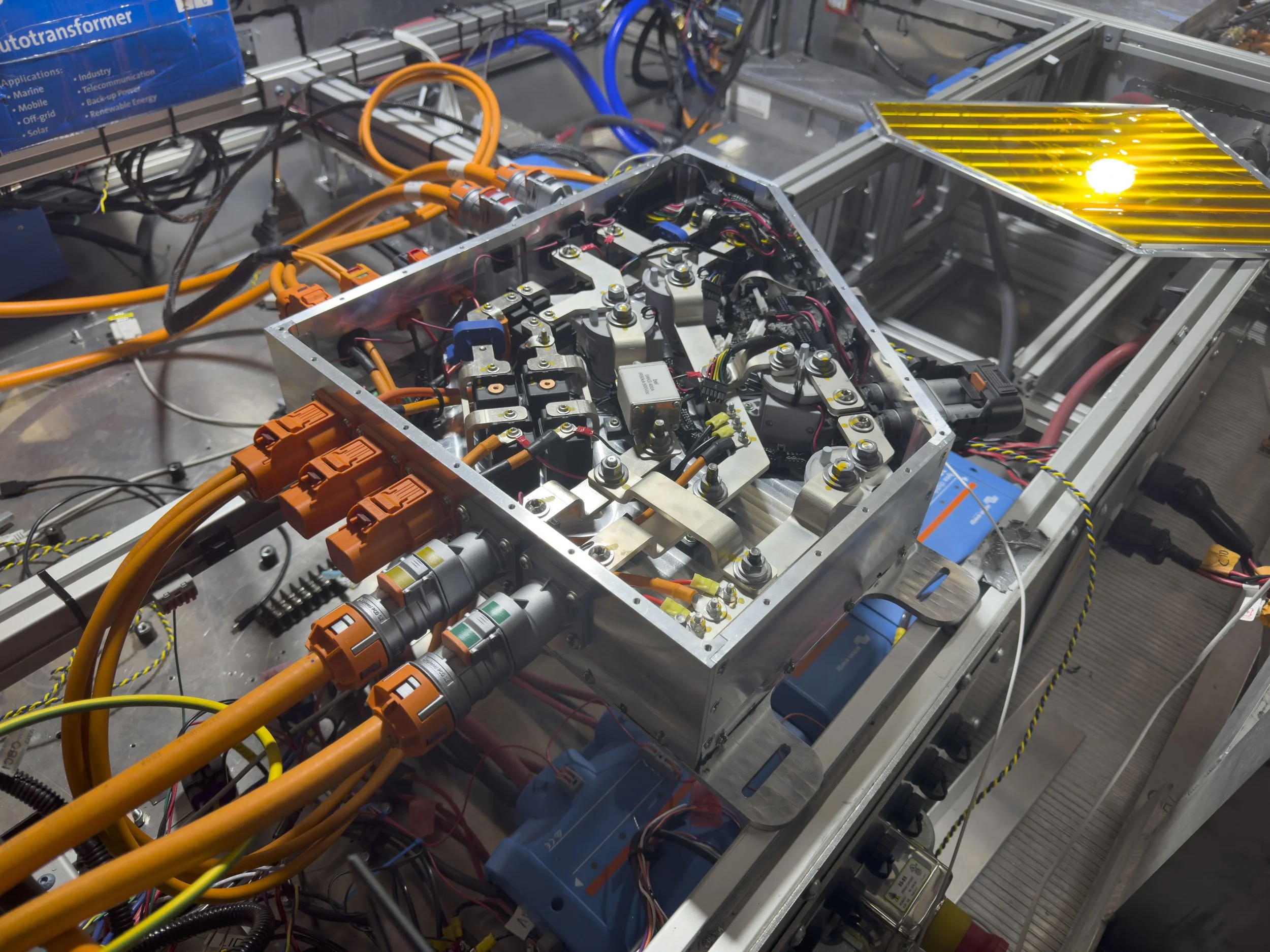

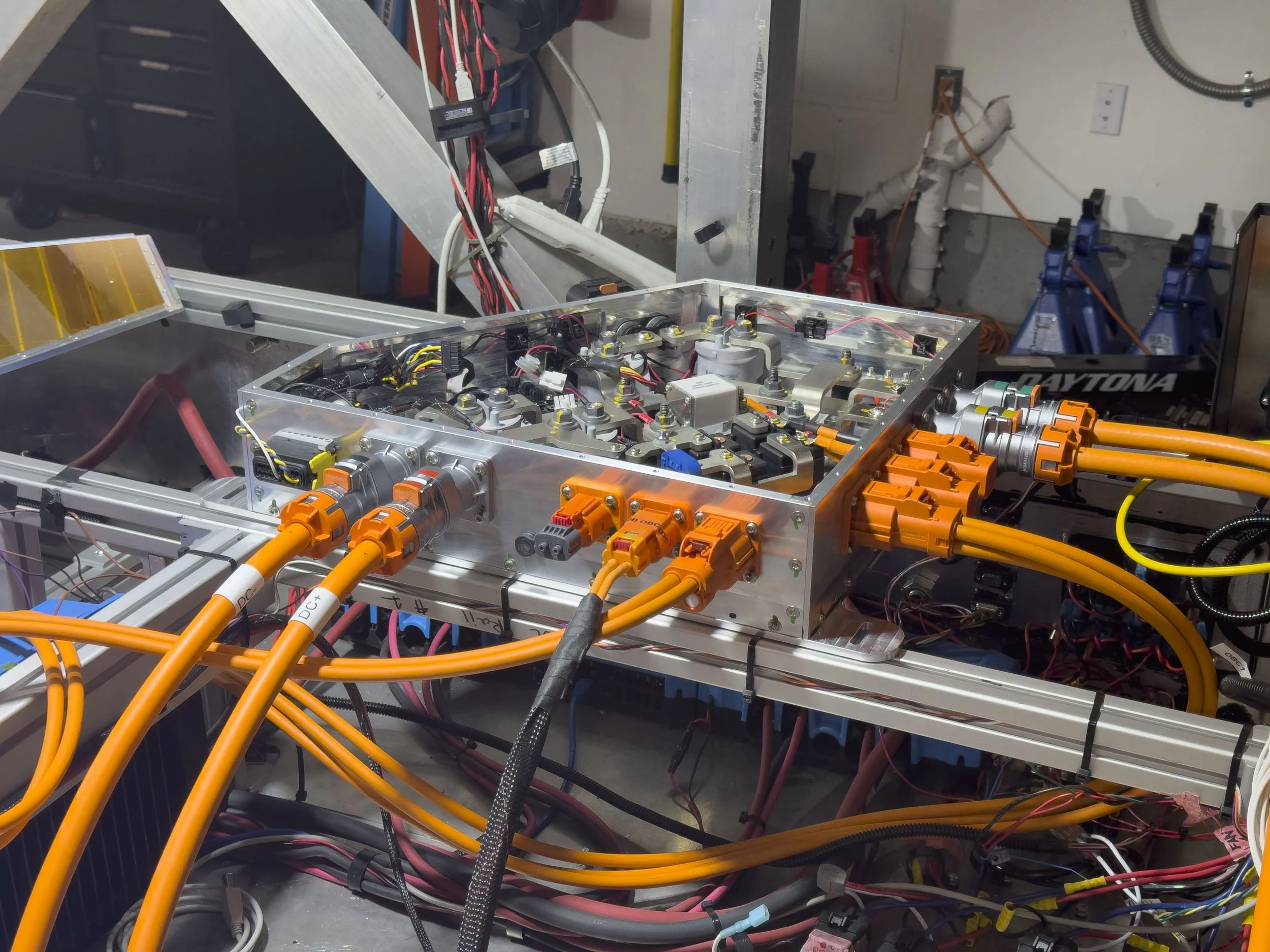

Billet HVJB internals

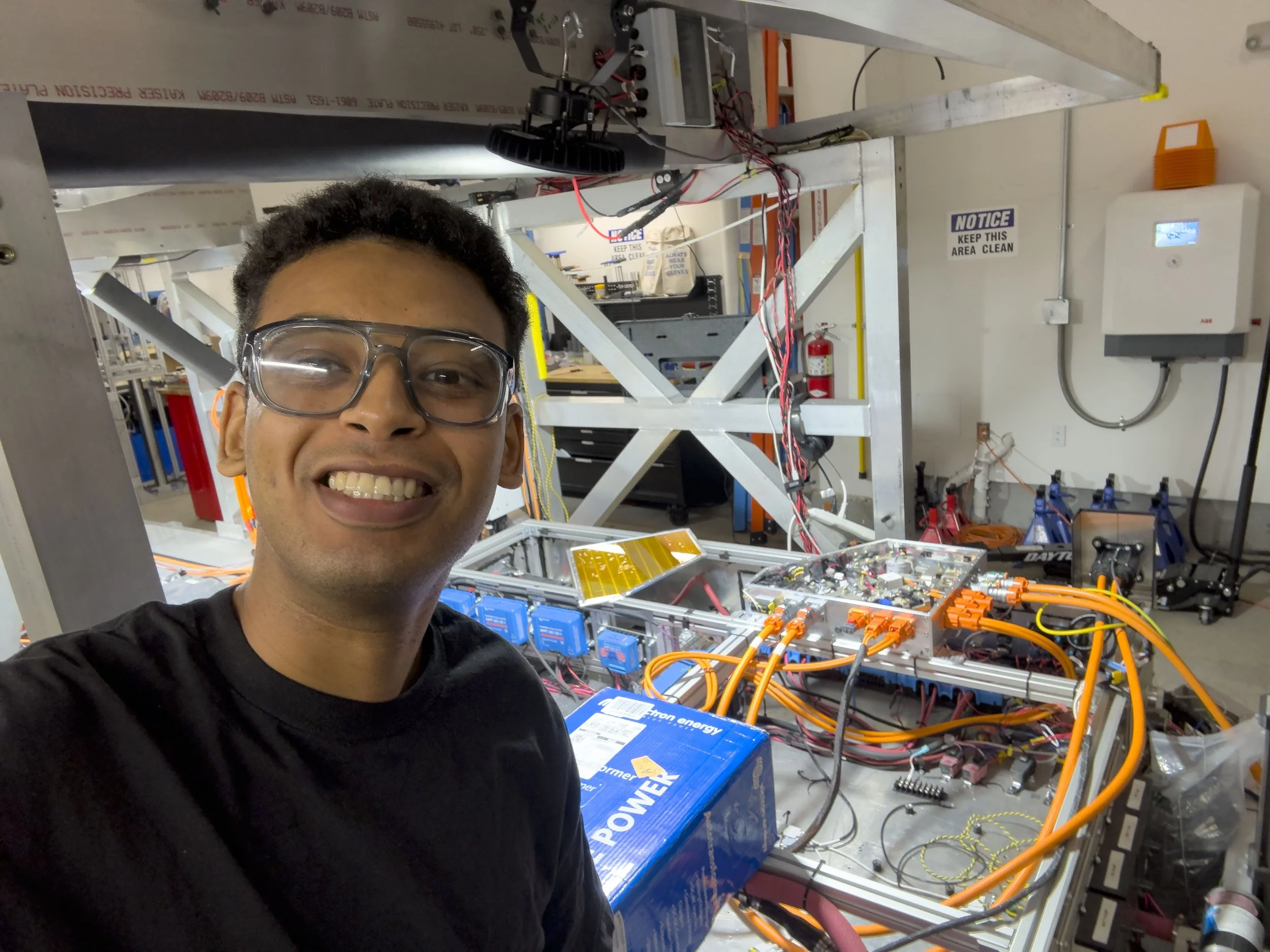

Hooked up and working!

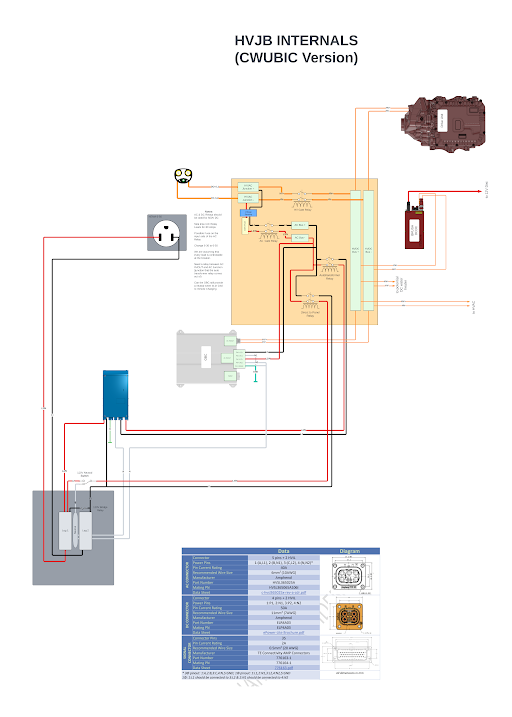

System diagram I created

IP testing..

More leak testing..

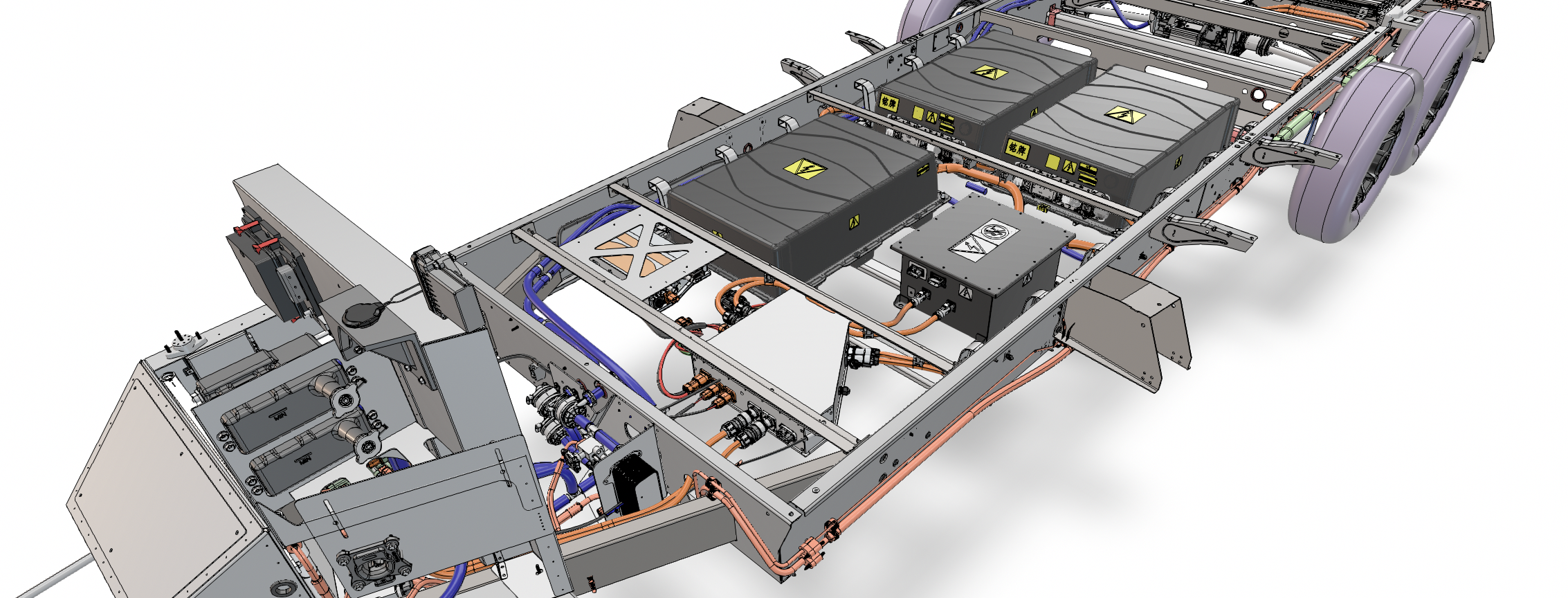

CAD of the underbody of the vehicle that I did, I positioned all the batteries, created all the harnessing, and conceptualized and executed on the overall package. A different engineer was responsible for the frame however.

Installed in a vehicle

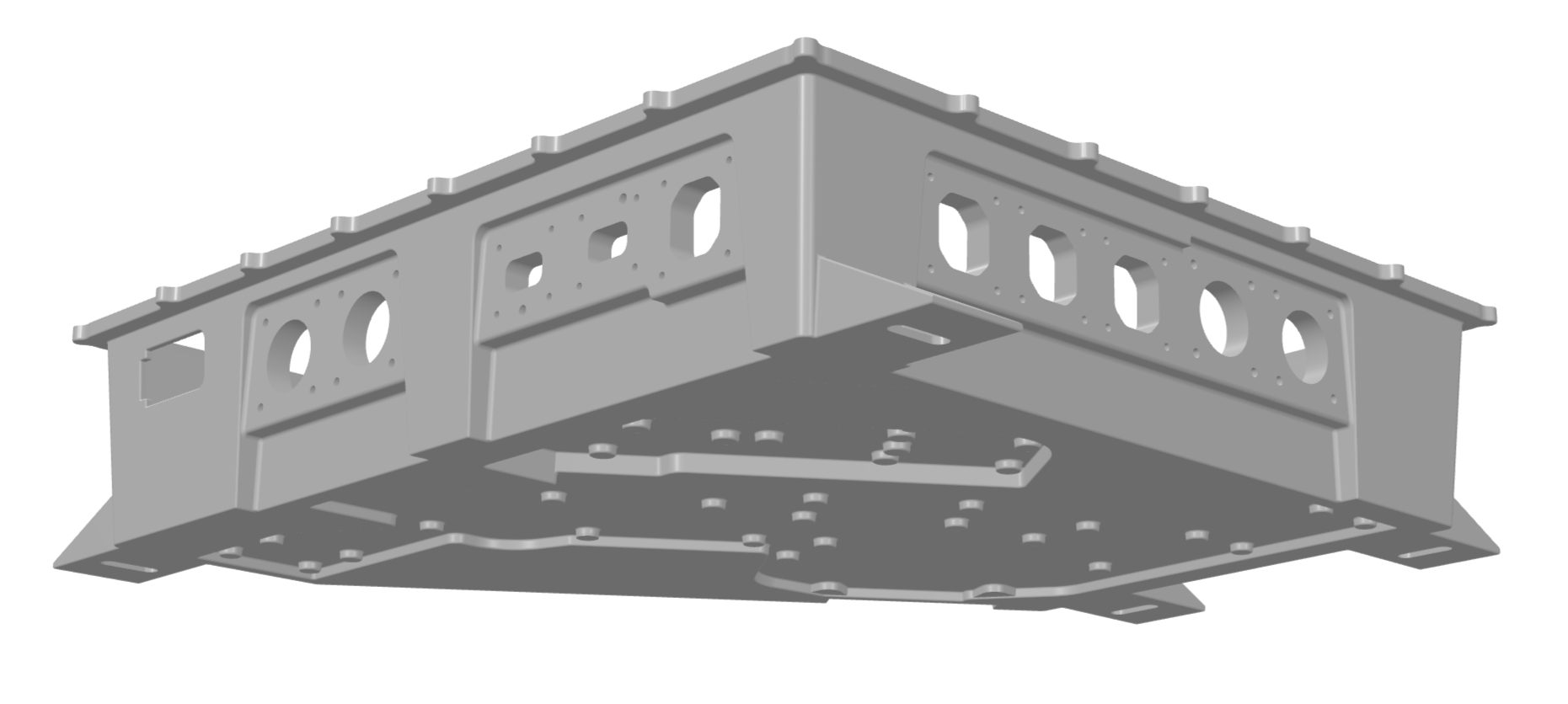

Cast version I designed that we didn't end up making since we didn't want to commit to tooling just yet

Cast enclosure

Top view of cast design

The difference between the billet aluminum version and a 3D print of the cast version